Fire Sprinklers

- Fire Sprinklers

- Standard Coverage

- Commercial Extended Coverage

- Storage Sprinklers

- Residential Sprinklers

- Dry Barrel Sprinklers

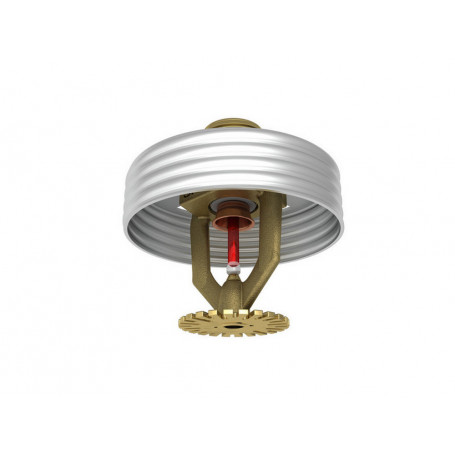

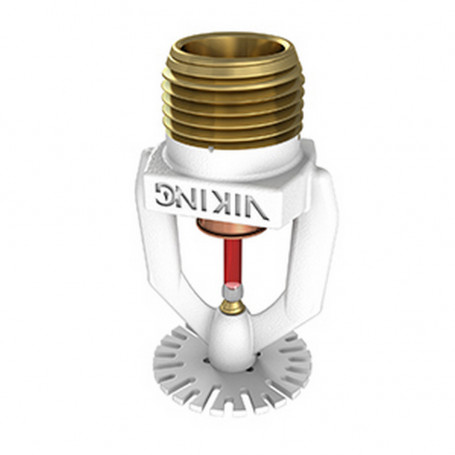

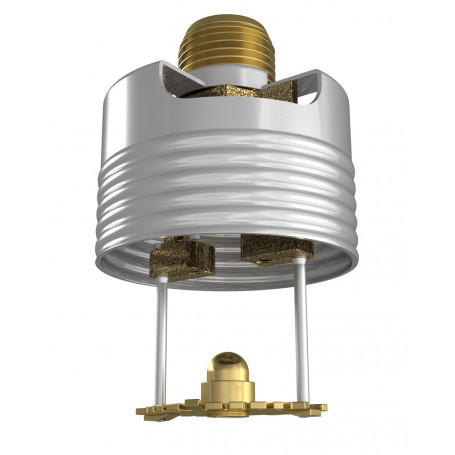

- Special Sprinklers

- Sprinkler Accessories

- Spray Nozzles / Window Protection

- Wet Pipe Systems

- Dry Pipe Systems

- Deluge Systems

- Preaction Systems

- Model G Preaction Systems

- Single Interlocked – Pneumatic Release

- Single Interlocked – Electric Release

- Double Interlocked – Pneumatic/Pneumatic Release

- Double Interlocked – Electric/Pneumatic Release

- Double Interlocked – Electric/Pneu-lectric Release

- Components and Accessories (general)

- Accessories (Pneumatic Release)

- Accessories (Hydraulic Release)

- Accessories (Electric Release)

- Alarm Devices

- Special Valves and Trim

- Valves and Systems

- Foam Systems and Accessories

- Foam Systems

- Concentrate Control Valves and Trim

- Valve Trim for Premixed Foam Systems

- Release Trim Packages

- Foam Concentrates

- Accessories, Foam Concentrates

- Proportioning Devices

- Discharge Devices

- Bladder Tanks

- Double Wall (SAFE) Atmospheric Storage Tanks

- Single Wall Atmospheric Storage Tanks

- Atmospheric Storage Tank Optional Equipment

- FoamPak Foam Pump Skid, 60Hz, Single and Dual

- FoamPak Foam Pump Skid, 50Hz, Single and Dual

- FoamPak Accessories

- Miscellaneous

- Portable Fire Equipment

- Fire Detection Systems

- Addressable Fire Alarm Systems

- Vigilant MX1 Addressable Panels

- MX1 Addressable Fire Panels

- AS1668 Controls and Gas Controls for MX1

- Addressable Detection & 850EMTK Programmer

- Addressable Modules and Field Devices

- Graphic Monitoring Software - XLG Client Server

- Vigilant Empty Cabinets & Battery Boxes

- IP Interface Networking

- MX Hazardous Detectors / Devices

- Documentation and Manuals

- Vigilant MX4428 & F4000 Addressable Systems

- ASE Parts

- Vigilant MX1 Addressable Panels

- Emergency Warning Systems

- QE20 EWCIE and QE90 EWIS

- Occupant Warning Systems

- Grade 2 and 3 EWS T-Gen2 AS4428.16 Approved

- Grade 2 and 3 EWS T-Gen2 AS4428.16 Approved

- Older Style OWS Amplifiers

- Evacuation Speakers

- WIP Phones & WIP Cabinets

- VOX Speech Intelligibility Test Kits

- Miscellaneous Tools & Items

- Conventional Fire Alarm Systems

- Maintenance Testing Equipment

- Flame Detection

- Ancillaries

- Cabinets

- Speaker Testing Equipment

- Miscellaneous Spare Parts

- Coltraco - Ultrasonic & Safety Instrumentation

- Photoelectric Smoke Alarms Stand Alone – Battery Powered

- OSID Emitters & Imagers

- Anti-Tamper Device

- FBA

- Gas Panel Signage

- Looms and Ribbon Cables

- Power Supplies

- Addressable Fire Alarm Systems

- VESDA ASD Detectors

- VESDA & FAAST FLEX Detectors

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA LCD Programmer & High Level Interfaces

- VESDA-E Backward Compatibility Table - Firmware Versions

- Filters & Spare Parts

- VESDA Software

- Pipe and Fittings

- Automatic Air Purging System

- 19" Rackmount Configurations

- Gas Detection for VESDA

- VESDA Remote Displays

- Power Supplies

- VSM4 Configuration & Monitoring Software

- VESDA Documentation & Manuals

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA-E Backward Compatibility Table – Firmware Versions

- VESDA Product Manuals & Data Sheets

- VESDA Technical Tips

- VESDA Maintenance & Troubleshooting

- VESDA Design & Commissioning

- VESDA Industry Documents

- VESDA Aspirated Smoke Detection for Impulse (Jet) Fans in Carparks

- VESDA Refrigerated Cold Storage Facilities - Design Guide & Information

- VESDA Case Studies

- VESDA Movies

- Smoke Bombs & Smoke Pens

- FAAST FLEX Documentation & Manuals

- Suppression Systems

- Hangers & Fasteners

- Exit & Emergency Lighting

- Foam Products

- Electrical Products

- Steel Pipe & Fittings

- Alarm Devices & Monitoring

- Signage & Blazons

- Tools & Accessories

There are 28 products.

Fire Sprinklers

Viking are industry leaders in quality and innovation, providing the broadest line of innovative and dependable fire sprinklers.

Subcategories

Standard Coverage

Commercial Extended Coverage

Storage Sprinklers

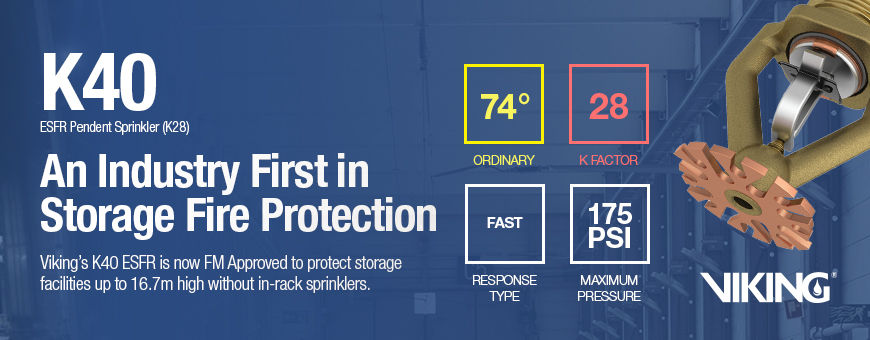

Early Suppression Fast Response (ESFR) Sprinklers

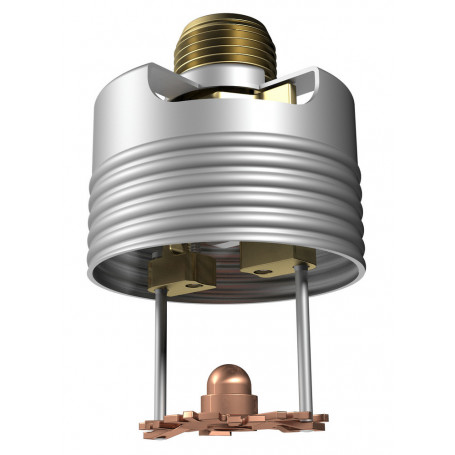

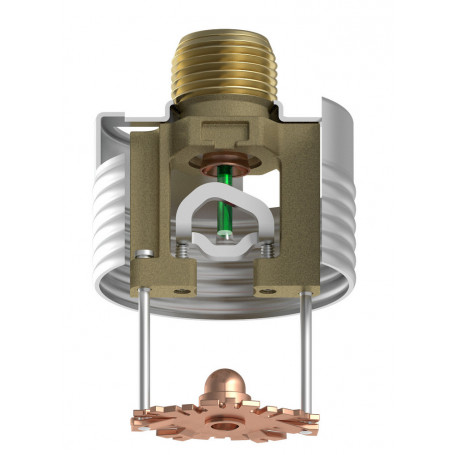

Viking’s Early Suppression Fast Response (ESFR) Sprinklers are high volume ceiling mounted sprinklers that exceed in the protection for severe challenging fires such as palletised and solid pile storage and single, double, and portable open rack storage (no open-top containers or solid shelves). A key advantage of an ESFR system over a Conventional sprinkler system is the possible elimination of the requirement for in-rack sprinklers in rack storage areas. ESFR systems are also specially designed to suppress the fire by discharging a large volume of water directly to the fire to reduce the heat release rate, while regular systems aim to simply control the fire.

Viking’s Model VK514 is now FM Approved as a Quick Response Storage Sprinkler providing ceiling-only sprinkler protection for storage facilities up to 16.7m in height. The K28 ESFR can help increase racking flexibility while also reducing the installation and maintenance costs associated with in-rack sprinklers. It has a Design Pressure of 5.5 bar. The K28 is available in ordinary and intermediate temperature ratings - 74° C and 96° C.

Residential Sprinklers

Residential Sprinkler Quick Reference Guide

This guide is intended for general reference only. Prior to the design, layout, and/or installation of any sprinkler system, please refer to the technical documentation and always consult with the AHJ. FlameStop makes no representation or warranty as to whether following this guide will satisfy any rule or requirement. Please visit our downloads section for the most current technical data and product specifications. All products must be installed in accordance with the manufacturer's current installation instructions. FlameStop reserves the right to change product specifications at any time without notice and without incurring obligation.

Pendent Style Sprinklers

Pendent and Recessed Pendent Flate Plate Concealed Pendent Domed Concealed Pendent Flush Concealed Pendent 3.0K 4.3K 4.9K 5.2K 5.8K 7.4K GB - Glass Bulb

FL - Fusible Link

** - New XT1 Platform(NOTE) The above photos are for illustrative purposes only and might not exactly match the sprinkler indicated. Always refer to the technical documentation for product dimensions and physical characteristics.Non-Pendent Style Sprinklers

Upright Horizontal Sidewall Flat Plate Concealed Sidewall 3.0K 4.0K 4.2K 4.9K 5.8K GB - Glass Bulb

FL - Fusible Link

** - New XT1 Platform(NOTE) The above photos are for illustrative purposes only and might not exactly match the sprinkler indicated. Always refer to the technical documentation for product dimensions and physical characteristics.Dry Barrel Sprinklers

Dry Pendent ELO Sprinklers

Viking’s Standard Response and Quick Response Dry Pendent ELO Sprinklers are the first of their kind as the only FM Approved ELO dry barrel models. With a nominal K-factor of 11.2 (161), the new sprinklers can reduce the overall water demand required in many cold storage sprinkler systems, particularly where ceiling heights are 35 ft. (10,5 m) and below. By reducing water supply requirements, Viking’s new dry ELO sprinklers can help lower system costs by possibly eliminating the need for a fire pump and reducing the size of system piping and related components. Plain barrel, standard adjustable, and recessed adjustable models are all available in both standard and quick response options.

- The only FM Approved ELO dry barrel pendent sprinkler.

- Ideal for a wide variety of low temperature commercial and cold storage applications subject to temperatures below 40° F.

- 1 ¼” barrel and thread size – requires 1 ¼” tee.

- Lengths in 6” increments from 12” to 48” (305 to 1,219 mm) for plain barrel, standard adjustable, and recessed adjustable models.

- Available in ordinary, intermediate, and high temperature ratings; 165° F (74° C), 205° F (96° C), and 280° F (138° C).

Special Sprinklers

Sprinkler Accessories

Spray Nozzles / Window Protection

Wet Pipe Systems

WetSystem

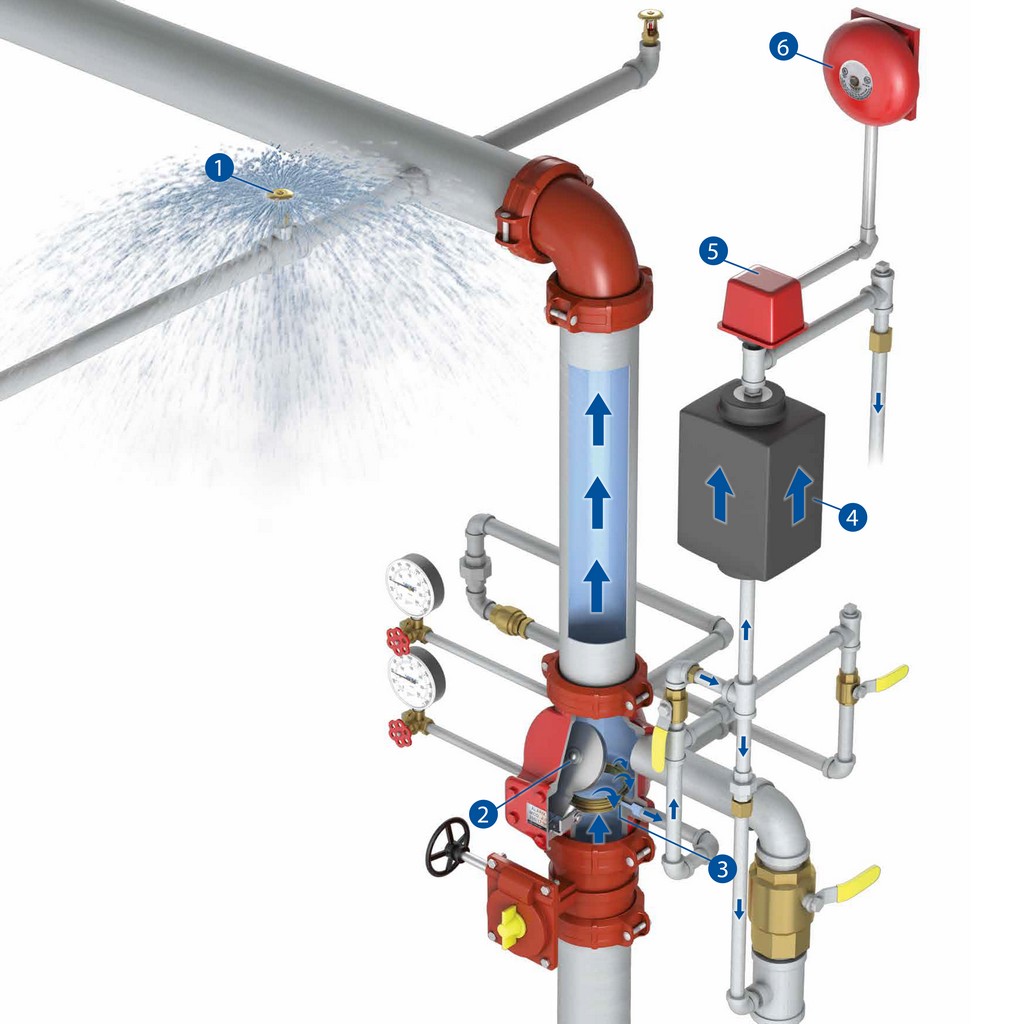

When a sprinkler (1) opens, the discharging water lifts the alarm valve clapper (2) and flows through the alarm port (3) to the retard chamber (4). When the retard chamber is filled, water flows to the water motor alarm and/or the optional pressure switch (5) which signals an electric alarm bell (6).

When a sprinkler (1) opens, the discharging water lifts the alarm valve clapper (2) and flows through the alarm port (3) to the retard chamber (4). When the retard chamber is filled, water flows to the water motor alarm and/or the optional pressure switch (5) which signals an electric alarm bell (6).

Dry Pipe Systems

Wet, Dry, Deluge & Preaction

There are 4 common types of sprinkler systems, Wet, Dry, Deluge & Pre-Action.

WET

Wet systems are the most common as they are the simplest of the 4 and usually require the least maintenance.

DRY

Dry systems designed for environments with freezing temperatures like walk-in refrigerators, loading docks, and warehouses. The piping does not contain any water, it is charged with air or nitrogen under pressure.

DELUGE

Deluge systems are designed for when large quantities of water are needed quickly to control a fast-developing fire.

PRE-ACTION

Pre-Action systems are hybrid dry/wet fire protection systems. They are similar to a deluge system except the sprinklers are closed. Specifically designed to protect water sensitive facilities such as libraries, data centres and museums, etc.

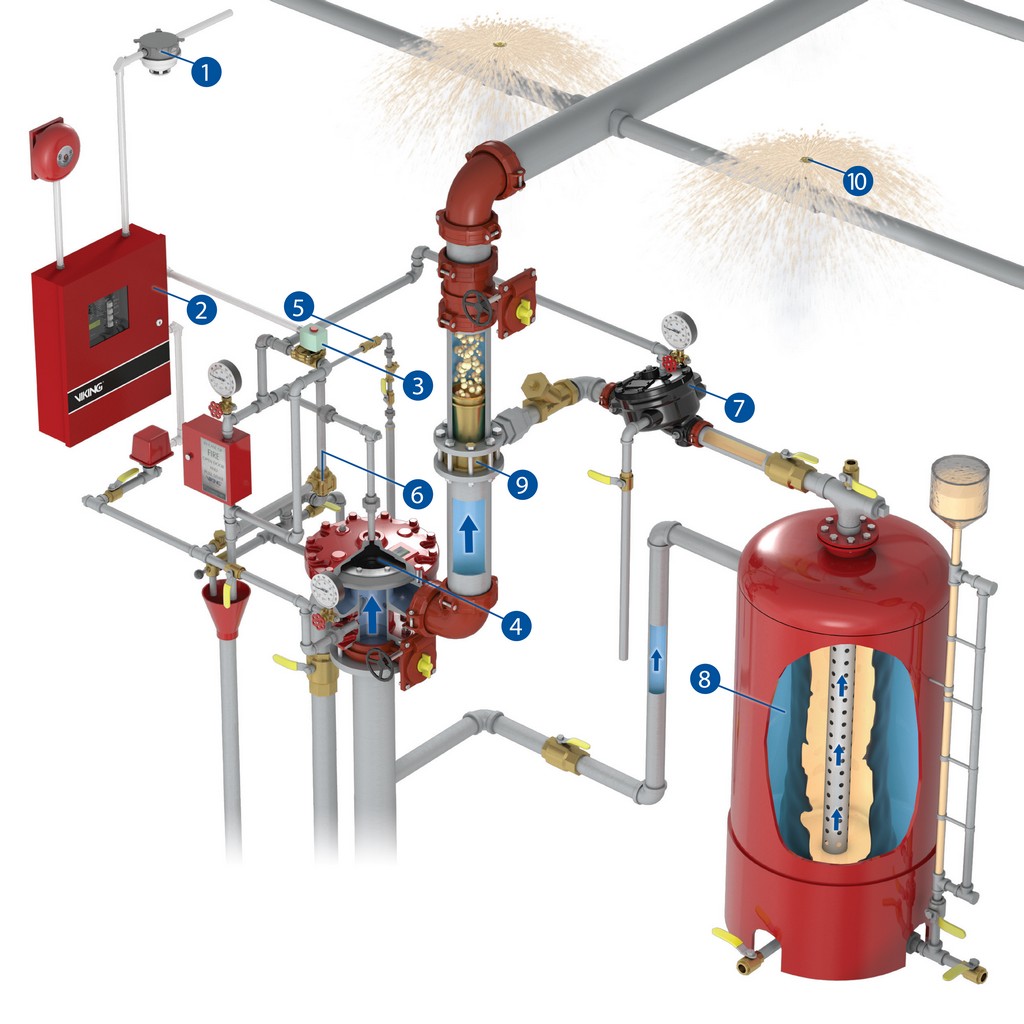

Deluge Systems

Foam/Water Deluge Sprinkler System

When the detector (1) is activated by fire, a signal is sent to the VFR-400 Release Control Panel (2). The panel sends appropriate alarm signals and, at the same time, signals the release of the solenoid valve (3). The deluge valve priming chamber (4) is then vented faster than water is supplied through the restricted orifice (5), allowing the deluge valve to open. When the deluge valve operates, pressure opens the pressure operated relief valve (PORV) (6) continuously venting the water to the priming chamber, ensuring the deluge valve remains in the open position. Trim piping, tied into the priming chamber of the Halar-coated concentrate control valve (7), allows that valve to open at approximately the same time, opening the foam concentrate line to the sprinkler system. The outer shell of the bladder tank (8), pressurized by system water, squeezes foam concentrate out to the proportioner (9). As water flows through the venturi area of the proportioner, a metered pressure drop draws foam concentrate into the system water creating a foam solution mixed to the appropriate ratios. This solution then flows through the sprinkler piping and out to the open sprinklers or nozzles (10)

Preaction Systems

Wet, Dry, Deluge & Preaction

There are 4 common types of sprinkler systems, Wet, Dry, Deluge & Pre-Action.

WET

Wet systems are the most common as they are the simplest of the 4 and usually require the least maintenance.

DRY

Dry systems designed for environments with freezing temperatures like walk-in refrigerators, loading docks, and warehouses. The piping does not contain any water, it is charged with air or nitrogen under pressure.

DELUGE

Deluge systems are designed for when large quantities of water are needed quickly to control a fast-developing fire.

PRE-ACTION

Pre-Action systems are hybrid dry/wet fire protection systems. They are similar to a deluge system except the sprinklers are closed. Specifically designed to protect water sensitive facilities such as libraries, data centres and museums, etc.

Valves and Systems

Valves & Systems

Viking offers customers a wide range of vales and systems, from Butterfly Valves through to Wet Pipe Systems. Our individual item page attachments gives you access to a wealth of information on each product.

Foam Systems and Accessories

For over 100 years, Viking has been a trusted name in fire protection. Our reputation has been earned by delivering unmatched product quality, integrated solutions, and experienced customer service and technical support at every point in your project process. We offer thousands of the finest fire protection products through Viking SupplyNet, our global network of distribution and fabrication centers.

Now you can rely on Viking for all your foam-water fire suppression needs. Our complete systems, backed by our decades of experience and the highest level of customer support, give you a seamless, integrated fire protection solution.

Foam System Solutions

Viking foam systems are designed to distribute a foam-water solution to a specific hazard area within a protected facility. Typical facilities include incineration plants, logistic centers, aircraft hangars, refineries, and many other areas where flammable liquid spill fires could occur. The type and potential size of the hazard determines the number of discharge devices, type of foam concentrate, and foam-water discharge rate and duration. Characteristics of some flammable products may require higher densities and special foam liquid concentrates.

NFPA 11 and EN13565-2 contain requirements for foam-water systems, with requirements for foam systems also found in NFPA 13, NFPA 16, NFPA 30, NFPA 409, and NPFA 418.

Viking - Tested and Trusted

Viking Foam Systems are FM Approved to FMS130 and UL Listed to UL162. These test standards require that foam system components – including foam concentrate, proportioning devices, storage tanks, and discharge devices - are tested together and approved or listed as a complete system. Many Viking products have also been tested to local approval standards. See Viking technical datasheets for details.

Viking Bladder Tanks carry ASME BPVC Certification, and conform to the rules governing the design, fabrication, assembly, and inspection of boiler and pressure vessel components during construction.

Miscellaneous

- 1

- 2

- 1

- 2